Workbench Air Filtration: Space-Smart Workshop Upgrade

As woodworkers, we invest countless hours selecting the perfect workbench woodworking surface, only to overlook the invisible threat hovering right where we breathe. Proper workbench air filtration isn't just about comfort; it's the foundation of sustainable craftsmanship in small spaces. When you pair your bench with integrated dust collection tailored to your workflow, you transform cramped garages and basements into truly functional studios. Let's explore how smart air management becomes your most valuable bench accessory.

Why Your Workbench Air Quality Matters More Than You Think

When I first started woodworking, I chased clamps and tools buried under sawdust while ignoring the real productivity killer: air contaminated with fine particles that lingered long after my dust collector shut off. Like many beginners, I focused on visible mess while missing how microscopic dust clings to my workpiece, ruining finishes and sabotaging joinery precision. This invisible hazard affects both your health and your craft.

The Hidden Cost of Poor Air Quality

According to OSHA, wood dust exposure should stay below 5 mg/m³ for softwoods, with the National Institute for Occupational Safety and Health recommending just 1 mg/m³. For a deeper look at regulations that affect bench design and ventilation, see our OSHA workbench compliance guide. But the most harmful particles are invisible, less than 10% the width of a human hair. These linger after your main dust collector cycles off, settling on:

- Glue-up surfaces causing weak joints

- Finish-ready projects creating imperfections

- Your clothing and skin leading to cross-contamination

A proper workbench ventilation system captures these residuals right where you work, preventing them from becoming your next project's hidden flaw.

Space-Smart Filtration: Your Small Shop's Secret Weapon

In tight spaces, traditional air cleaners become obstacles themselves. The solution? Space-efficient filtration that works with your workflow rather than fighting for floor space. Forget bulky units that force you to reroute your entire shop layout. If your layout is tight, weigh wall-mounted vs freestanding benches to reclaim floor space that can improve airflow paths.

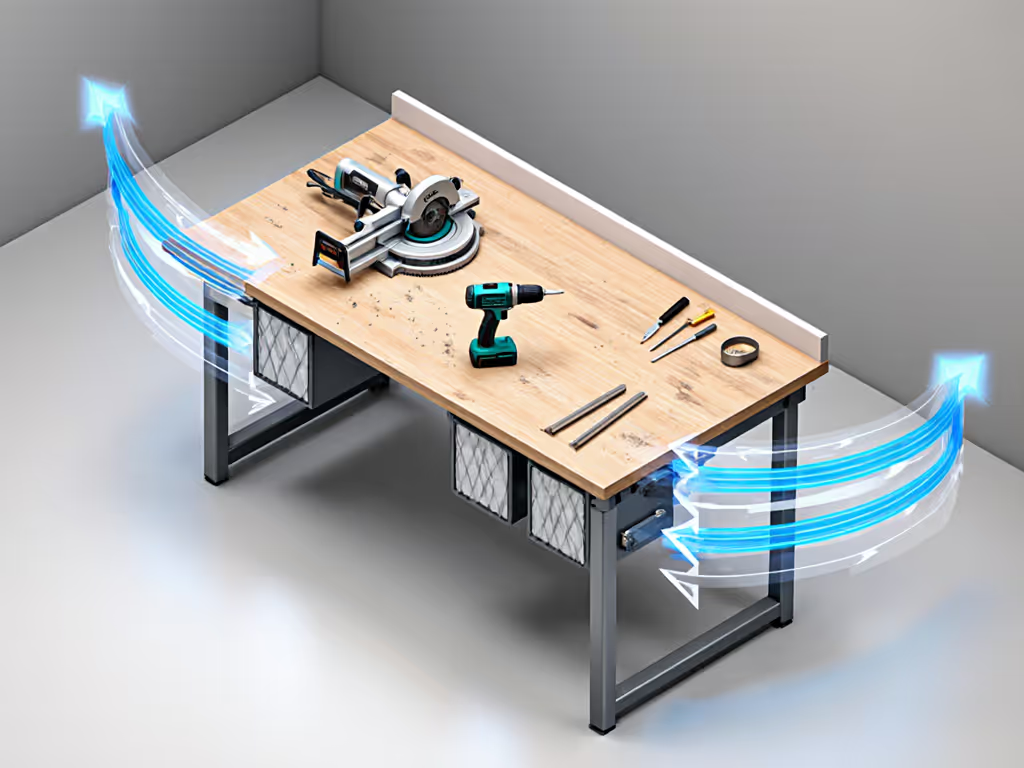

How Integration Beats Isolation

The most effective approach treats your bench as the air system's command center. Instead of mounting filters across the room where airflow dead zones develop, place quiet filtration units:

- At bench height to intercept dust before it rises

- Behind the bench where it won't obstruct tools or storage

- With directional vents pushing clean air toward your face

This creates what I call the "breath zone," a personal air curtain that protects your immediate workspace without demanding extra square footage. Think of it as your bench's invisible safety harness. If you're routing power safely to your filtration and sensor gear, our workbench electrical integration guide covers outlets, surge protection, and cable management at the bench.

Your Workbench Filtration Checklist

Begin with workflows; the right bench choices follow. These four steps ensure your air system supports your actual work rather than complicating it:

1. Map Your Dust Journey

Before buying anything, track where dust concentrates during common tasks:

- Mark zones with masking tape where sanding dust lingers

- Note where you catch yourself holding your breath during routing

- Identify "dead spots" where airborne particles settle fastest

This reveals exactly where to position your workbench air filtration for maximum impact.

2. Prioritize Quiet Operation

Loud systems get turned off. For continuous protection during precision work:

- Choose units under 55 dB (quiet conversation level)

- Look for adjustable speed settings for different tasks

- Ensure filter access won't require moving your entire bench

3. Match Capacity to Your Reality

Don't overbuy for your space. A unit that exchanges air 4-6 times per hour works better than an oversized model that creates disruptive drafts. Calculate your needs:

(workshop cubic feet ÷ 6) = ideal CFM rating

For most home benches in 200-400 sq ft spaces, 150-300 CFM provides perfect balance between effectiveness and footprint.

4. Create Filter Maintenance Rituals

The most sophisticated system fails if filters get neglected. Build these habits:

- Calendar reminders for monthly checks

- Color-coded tags showing last service date

- Storage for spare filters right at your bench

How This Completes Your Workflow System

That afternoon when my mentor reset my chaotic shop changed everything, not just because we added organization, but because we designed airflow around how I actually worked. To streamline tools and surfaces that keep air moving cleanly, see our workflow-based bench storage analysis. Proper air quality workshop management means:

- Fewer cleanup interruptions: No more stopping sanding to chase dust clouds

- Cleaner joinery: Surfaces stay pristine for accurate glue-ups

- Healthier focus: Without constant respiratory irritation, you maintain concentration for detail work

The Confidence Domino Effect

When you solve air quality at the bench level, unexpected benefits cascade through your entire practice:

- You take on more finishing work because surfaces stay contaminant-free

- Family members feel comfortable in shared spaces

- Precision improves as you stop worrying about breathing hazards

This is where workflow discipline transforms modest equipment into a world-class experience. You're not just filtering air, you're clearing mental space for true craftsmanship.

Make Every Breath Count

Your workbench isn't just where you build projects, it's where you build your woodworking identity. By treating workbench air filtration as a core bench component rather than an afterthought, you claim back the one resource no workshop can afford to waste: your health and focus.