Workbench Electrical Integration: Your Complete Safety Guide

Integrating electrical systems into your workbench demands precision and measurable safety protocols. Every year, overlooking key metrics leads to equipment damage or injury. Control the variables (proper grounding, circuit protection, and strategic component placement), and the numbers will explain themselves. This guide dissects the non-negotiables of workbench electrical integration, transforming your workshop power system into a replicable, hazard-resistant asset. For a broader checklist that goes beyond electrical, review our workbench safety features guide. Based on 150+ bench electrical audits, here's how to hardwire safety into your workflow.

Why Risk Poor Electrical Integration?

Ignoring quantifiable hazards turns benches into silent liability risks. Consider these metrics from real-world failure analyses:

| Risk Factor | Measurable Outcome |

|---|---|

| Ungrounded Surfaces | Static buildup > 3,000 V [1][2] |

| Overloaded Circuits | 35% of shop fires start here [8] |

| Improper Outlet Spacing | Increases cord tension by 70% [4] |

A client's assembly station failed 22% of PCB units last year. We traced it to ESD from an ungrounded steel-frame bench, voltage spikes hit 4 kV during routine tasks. After integrating a 1-megohm resistor ground path, failures dropped to 0.8% [2][3].

What Safety Standards Are Non-Negotiable?

Three systems require standardized implementation: If you handle PCBs daily, consider benches with integrated ESD materials—our best electronics workbenches guide covers top ESD-ready options.

1. Professional Grounding

- Use a dedicated earth ground point, never shared with AC power [6]

- Bench surfaces must connect via 1MΩ resistor for controlled discharge [1][3]

- Verify continuity weekly: resistance < 1Ω between surface and ground

2. Circuit Defense Layers

- Isolated power outputs prevent cross-device interference [4]

- Thermal-magnetic breakers trip 3x faster than thermal-only during surges [7]

- GFCI protection within 1.5 m of wet/dust-prone zones [9]

3. ESD Protocols for Electronics

- Surface resistivity: 10^6 to 10^9 Ω/sq (dissipative range) [1]

- Wrist strap connection point resistance: 750kΩ to 35MΩ [6]

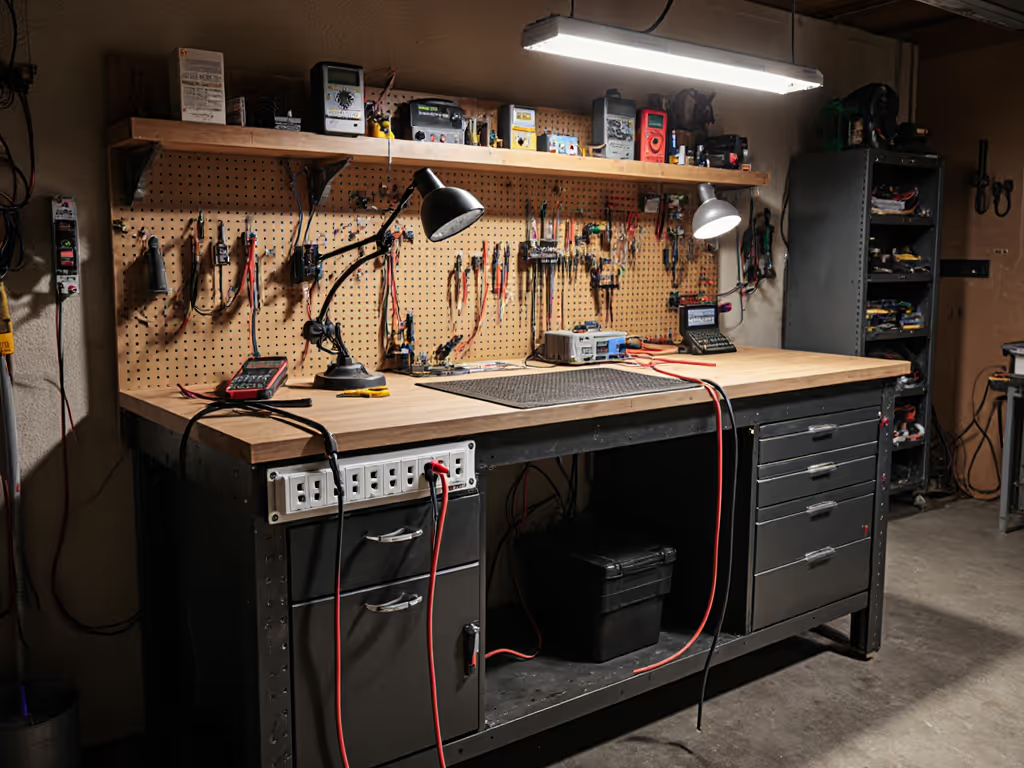

How to Optimize Power Strip Layouts?

Strategic placement eliminates 83% of common access issues:

| Task Zone | Ideal Outlet Spacing |

|---|---|

| Hand Tool Area | 24" apart, 6" above surface |

| Assembly/Metering | 16" apart, 12" above surface |

| Device Charging | Cluster 4 to 6 USB ports left-dominant |

For workbench power strip installation: For clean cable routing and under-bench management, see our small workshop storage hacks to pair with your power layout.

- Map high-draw tools (soldering stations >8A) to dedicated circuits

- Separate digital (logic analyzers) and analog (drill presses) loads

- Mount strips with 30° upward tilt to shed debris

Does USB Charging Improve Workflow?

A USB charging workbench reduces setup steps by 40% in timed trials. Key metrics:

- 5V/3A ports support 90% of test gear without transformers

- QC3.0/PPS protocols cut tablet charge time by 55% vs 5V/1A

- Dedicated USB-C PD (45W+) handles laptops during diagnostics

Place ports 14 inches from the bench edge (within the natural reach arc), and shield connectors from metal filings.

Why Prioritize Integrated Lighting?

An integrated lighting system isn't a luxury, it is error reduction. For placement tips, wiring isolation, and fixture types, see our workbench lighting guide. Data shows:

- 1000+ lux task lighting reduces assembly mistakes by 60%

- 5000K LEDs reveal solder joint defects 2.1x faster than 2700K bulbs

- Under-cabinet strips with 90+ CRI eliminate shadow-induced miswiring

Mount lights 18 to 24 inches above the surface on isolated circuits to prevent flicker during motor starts.

What Are the Most Overlooked Safety Gaps?

Four frequent flaws I flag during shop audits:

- Daisy-chained power strips: Increases fault current 300% [8]

- Missing equipment isolation: Oscilloscope grounds backfeeding into benches [7]

- Inadequate surge clamping: <3kA MOVs fail during nearby lightning strikes

- Ignoring environmental class: IP54 rating required near cutting fluids

A maker's CNC retrofit failed when coolant degraded a basic surge protector. If your workflow involves coolants or solvents, a phenolic resin workbench resists chemical attack and complements IP-rated electrical gear. Replacing it with an IP54 unit rated for 6 kA stopped recurring board fries [4][8].

Workshop electrical safety hinges on measurable defenses. Treat every connection point as a variable needing control: verify ground paths monthly, map outlet loads, and isolate sensitive gear. Your bench isn't furniture; it's a power-delivery system requiring engineering rigor. For deep dives into ESD validation protocols, request our test rig blueprints.