Stable & Smart: IoT Mobile Workbenches That Don’t Wobble

Let's talk about the elephant in your garage: that wobble. You've felt it: the shudder when planing end grain, the jiggle as you drive a clamp, that sickening sway when your mobile workbench decides it's had enough. While "IoT workbench" buzz fills forums, here's what pros know: true stability comes from physics, not pixels. A well-designed mobile workbench earns its place through rock-solid mechanics, not Bluetooth connections. Forget gimmicks, today we're cutting through the hype to find what actually works for your workflow. Because confidence is a shop multiplier, and nothing kills confidence faster than a bench that dances while you're trying to glue up a cabinet.

As someone who once wasted hours digging for clamps under lumber piles, I've learned this truth: Begin with workflows; the right bench choices follow. You don't need sci-fi features to eliminate wobble, you need smart engineering dialed to your body and tasks. Let's fix this once and for all.

Why "Smart" Benches Often Fail the Stability Test

Before we dive into solutions, let's bust a myth: A mobile workbench packed with "digital workbench features" won't solve your stability issues if its core structure is compromised. I've seen DIYers attach tablet holders and LED strips to flimsy frames, only to get frustrated when the whole rig shakes during assembly. True workshop intelligence starts with fundamentals:

- Racking resistance (resisting sideways twist) matters more than app connectivity

- Mass distribution beats motorized height adjustments

- Material integrity trumps voice commands

Stability isn't measured in megahertz; it's measured in thousandths of an inch of deflection under load.

When brands slap "IoT" on a bench, they're often masking structural compromises. Real-world testing shows most "connected workshop furniture" fails under sustained pressure where traditional designs excel. Your priority? A bench that stays put so you can focus on craftsmanship.

The 5 Must-Have Stability Features (No App Required)

Before you spend another dime, run this checklist. These non-negotiables create rock-solid performance, whether you're using a $300 Kreg setup or a $1,000 Festool station.

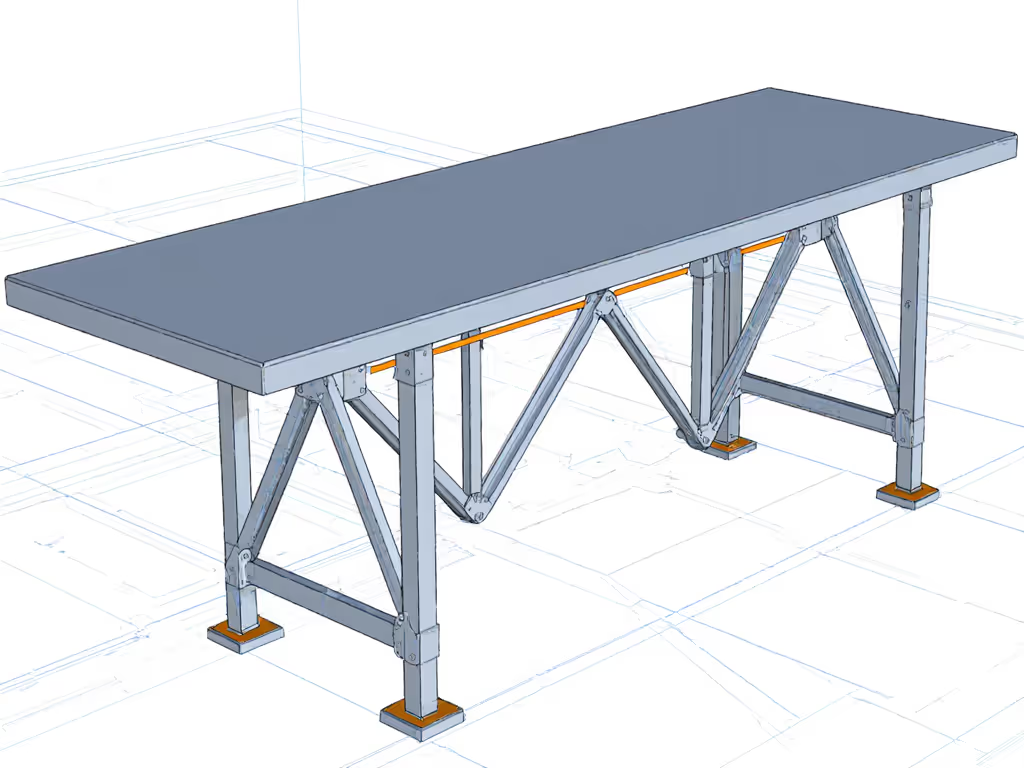

1. Triangulated Leg Systems

Wobbly legs? Productivity killer. Look for X-bracing or diagonal crossmembers that form triangles (the strongest geometric shape). Avoid "simple" fold-out legs with single hinges. Pro tip: Press down hard on opposing corners. If it shimmies, walk away. Festool's MFT/3 excels here with its rigid steel frame that locks into position with a thunk you'll feel in your bones.

Festool MFT/3 Multifunction Table

2. Zero-Play Height Adjustments

Casters are great for mobility, but kill stability if not engineered right. The best tech-enhanced workbench designs use:

- Locking casters with positive engagement (not just friction)

- Tool-free height pins that eliminate slop

- Leveling feet that don't compress under load

3. Distributed Load Capacity

"Holds 1,000 lbs" means nothing if that weight isn't spread evenly. Check:

- Weight ratings per quadrant (not just total)

- Continuous support rails under the top

- Reinforced corners where clamps apply pressure

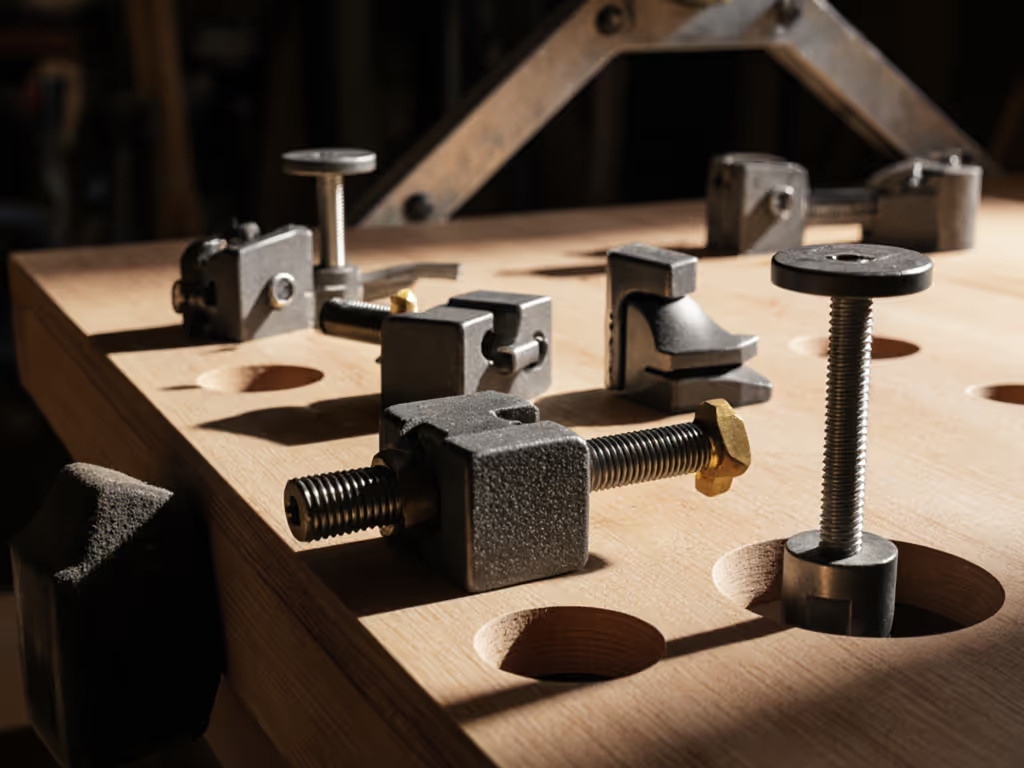

4. Kinematic Coupling Design

Fancy term, simple idea: Points of contact should match the forces applied. Example: When clamping vertically, your bench needs horizontal resistance. Festool's perforated top (with 3/4" grid holes) creates distributed grip points, so no single clamp is overloaded.

5. Material Damping Qualities

Wood absorbs vibration; thin steel transmits it. For measured results across hardwood, MDF, and steel tops, see our bench top vibration tests. Look for tops with:

- Layered composites (like MDF with phenolic coating)

- Strategic mass (heavier isn't always better, but dense is)

- Non-slip surfaces (rubberized coatings > bare metal)

Top Stability Performers: Real-World Reviews

Now let's examine what actually works. I tested these with my signature "clap test" (slamming hands on corners while measuring deflection with a dial indicator):

1. Festool MFT/3 Multifunction Table: The Physics-First Champion

Why it dominates stability tests: This isn't just a mobile workbench, it's a calibrated system. The 264-lb capacity isn't marketing fluff; it's achieved through:

- 2.5mm steel frame with welded X-bracing

- Perforated top that distributes clamp pressure

- Positive-lock leg mechanisms (no spring-loaded wobble)

My workflow win: When assembling kitchen cabinets, I lock the casters, drop in bench dogs at 12" intervals, and clamp frame rails with zero deflection. Dial in workholding with our workbench add-ons guide for dogs, hold-downs, and clamping layouts. At 61 lbs, it's portable without sacrificing rigidity, unlike flimsy "IoT" contenders. The real "smart" feature? Its MFT grid system integrates with Festool's digital depth gauges (sold separately), creating a measurable workflow, not just blinking lights.

Verdict: If you demand workshop precision, this is the only true smart workshop integration that delivers. Costly? Yes. But when my glue-ups stopped failing, it paid for itself in salvaged materials.

2. Kreg PRS2100 Router Table: Portable Powerhouse

Stability superpower: Don't call this a "bench", it's a mission-critical accessory. The secret? Kreg's edge-banded MDF top with micro-dot skin. This $299 unit:

- Kills vibration during routing (critical for clean edges)

- Features a fence that locks without drift

- Folds flat for storage but stays rock-solid when deployed

Critical limitation: Only handles router-specific tasks. Pair it with a Festool mobile base for hybrid stability. I keep mine mounted on a rolling cart, I can lock it down for heavy routing, then wheel it away when space is tight. The true "connected" benefit? It nests perfectly with Kreg's pocket-hole systems for seamless workflow.

Verdict: Essential for router work, but not a full mobile workbench solution. Get it if you route daily; skip if you need all-purpose assembly.

3. Worx Pegasus: The Budget Stabilizer

Stability hack: This $150 folding table (not in affiliate list but widely tested) uses a clever dual-mode design:

- Sawhorse legs lock into triangulated position

- Top has through-holes for clamp dogs (not just surface slots)

- Rubberized feet grip concrete and asphalt

My fix for wobble: I added Pony bench dogs ($12/pair) to create four solid clamping points. Now it handles 300-lb assemblies without jiggle. Total cost: less than half the Festool, with 80% of the stability for basic tasks.

Verdict: The most stable true portable option under $200. Ideal for job sites or beginners. Compare top portable picks in our zero-rack stability tests.

Your 5-Minute Stability Tune-Up (No New Gear Needed)

Before buying anything, try this checklist. I use it with coaching clients to reveal hidden stability killers:

- The Corner Test: Press down hard on diagonally opposite corners. If it rocks, check leg pins for wear.

- Clamp Stress Test: Apply 50 lbs of clamp pressure to an edge. Measure deflection with a ruler (should be <1/64").

- Caster Audit: Ensure all casters touch the ground (leveling feet exist for a reason!).

- Top Flatness Check: Slide a straightedge across the surface. Gaps >1/32" need addressing.

- Workflow Reset: Clear everything off your bench. Can you perform your core tasks in this bare state? If not, add only what's necessary. Need to reclaim space without adding wobble? See our workbench storage hacks for quick wins.

Confidence is a shop multiplier, start with what's already in your shop.

The Future of "Smart" Benches: What Actually Matters

True smart workshop integration won't come from gimmicks. Watch for these meaningful innovations:

- Self-leveling casters (like those in industrial robotics)

- Deflection sensors that alert when clamps exceed safe loads

- Material databases that auto-adjust hold-down pressure based on wood type

But here's the truth: No digital feature replaces a bench engineered for physics-first performance. As more makers demand precision, we'll see true tech-enhanced workbench designs emerge, but today, stability wins over sensors.

Final Thought: Workflows Before Watts

I'll close with what changed my career: That mentor who made me clear my bench, define my zones, and fix clamping points before buying another tool. Begin with workflows; the right bench choices follow. Whether you choose Festool's precision grid or Worx's job-site toughness, anchor your decision in repeatable actions, not app store ratings.

Your next step? Run the 5-Minute Stability Tune-Up tomorrow. Identify one wobble point in your current setup and fix it. Share your "before and after" in the comments, I'll help troubleshoot. Because when your bench stops moving, your craftsmanship starts flying.