Woodworking Workbench Top: Match Material to Project Needs

Let's face it, your woodworking workbench top isn't just a place to hold tools. It's the foundation of your entire workflow. I've seen countless beginners and returning woodworkers struggle because they chose a surface that fought against their projects instead of supporting them. Whether you're crafting delicate joinery or reshaping plastic, the right woodworking workbench tops eliminate frustration and turn chaotic sessions into satisfying progress. Today, we'll cut through the noise with a simple, checklist-driven comparison to match your bench top to what actually happens in your shop. No guesswork. No wasted weekends. Just surfaces that earn their space.

Why Your Bench Top Material Makes or Breaks Your Workflow

That first solo build where I lost hours chasing clamps under sawdust? It taught me this truth: Clear homes end clamp hunts. A bench top isn't about looks, it's about function. Will it stay flat during glue-ups? Can you clamp rigidly without marring the surface? Does it forgive a spilled solvent or resist a chisel slip? Your material choice directly impacts fatigue, accuracy, and joy. Let's compare the top contenders based on real project demands, not just specs on a box.

1. Hardwood Tops (Maple, Beech, Oak)

Best for: Precision joinery, hand-tool work, and general woodworking

Hardwood tops (like 3-inch-thick maple) are the gold standard for traditionalists. They offer gentle cushioning for chisels and planes, absorb vibration during handwork, and provide a warm, inviting surface. Seasoned woodworkers confirm they stay quieter than steel when tools slide across them. Crucially, they're repairable: sand out dents or plane flat if seasonal movement warps them. Maple's density resists dings better than softer woods, making it ideal for carving or paring.

Watch for: Moisture sensitivity. Unsealed wood soaks up glue or oil spills, leading to swelling or mold. Always apply food-grade mineral oil or polyurethane. Avoid if you regularly handle acidic chemicals or wet composites.

Remember: Begin with workflows; the right bench choices follow. Match your top to daily tasks, not dream projects.

2. Stainless Steel Tops

Best for: Metalworking, plastic fabrication, and chemical-heavy tasks

If you're asking what's the best surface for plastic fabrication, steel often wins. Its non-porous nature resists chemical splashes (like acetone or epoxy), won't warp under heat from soldering, and wipes clean instantly. For hybrid workshops handling metal or electronics, its ESD-safe variants prevent static damage. Many makers love its rigidity for heavy clamping (zero deflection during assembly). If you're weighing trade-offs, see our steel vs wood workbench comparison for stability, vibration, and cost data.

Watch for: The noise. Dropping a chisel echoes like a gong. It also conducts cold (uncomfortable in winter) and shows every fingerprint. Avoid for delicate hand-tool work where vibration dampening matters. Not the answer if you need glue release for composite workbench tasks.

3. Laminate Tops (Standard or ESD)

Best for: Budget builds, electronics work, and mixed-media shops

Laminate (especially industrial-grade) delivers surprising toughness at low cost. Standard laminate resists scratches better than bare plywood and cleans up fast after paint or resin spills. For electronics tinkerers, ESD-safe laminate prevents static discharge that fries circuits. It's lightweight, stays flat, and won't react with solvents. Ideal if your woodworking workbench design must handle circuit boards one hour and sanding the next.

Watch for: Edges chip under heavy impact. Once damaged, it's hard to repair. Not suitable for hot tools (soldering irons melt it) or tasks requiring dog holes (you'll need pre-drilled versions). Skip if you need a repairable surface.

4. Phenolic Resin & Epoxy Tops

Best for: High-moisture environments, chemical labs, and pro finishing stations

These tops laugh at spills. Phenolic resin resists acids, solvents, and extreme temps (-40°F to 280°F) — perfect for finishing stations where shellac or paint splatters fly. For buyers ready to spec this material, our phenolic resin workbench guide covers chemical resistance, heat tolerance, and top models. Epoxy creates seamless, non-porous surfaces that won't stain. Both offer exceptional flatness out of the box, critical for cabinetmakers doing precision glue-ups. Many choose them for composite workbench performance where chemical resistance is non-negotiable.

Watch for: Price tags. They cost 2-3x more than hardwood. Heavy too (50+ lbs for a 2x4 sheet). And while tough, deep gouges can't be sanded out like wood. Overkill for general woodworking.

5. HDPE (High-Density Polyethylene)

Best for: Temporary setups, mobile workstations, and glue-heavy tasks

HDPE's superpower? Nothing sticks to it. Glue, resin, or hot-melt adhesive peel right off. It's chemical-resistant, waterproof, and lightweight enough to toss in a truck bed. Budget-friendly for shed workshops or makerspaces needing disposable surfaces. Often used as sacrificial layers over a primary bench top.

Watch for: Low rigidity. It flexes under clamping pressure, ruining precision work. Also scratches easily and degrades in UV light. Never use as a standalone top for hand-tool woodworking. Great supplement, poor primary surface.

How to Choose: Match Your Top to Your Real Workflow

Stop overcomplicating this. Use this checklist:

- List your top 3 weekly tasks (e.g., "hand-planing doors," "epoxy river tables," "soldering circuit boards").

- Ask: Does this surface support those tasks? (Maple for planing, steel for epoxy, ESD laminate for soldering).

- Check your non-negotiables: Must stay flat? Resist chemicals? Repairable? Noise-sensitive?

- Test usability: Sit at your bench height. Does the surface feel stable when you push hard? Is cleanup effortless? If the height feels off, dial it in with our workbench height sizing guide.

Pro tip: If your workflow shifts often (e.g., furniture to electronics), go modular. A hardwood base with a removable HDPE or laminate topper lets you swap surfaces fast. No need to rebuild your entire bench.

Beyond Material: Optimize Your Workflow Now

Even a modest bench shines when your workflow is dialed:

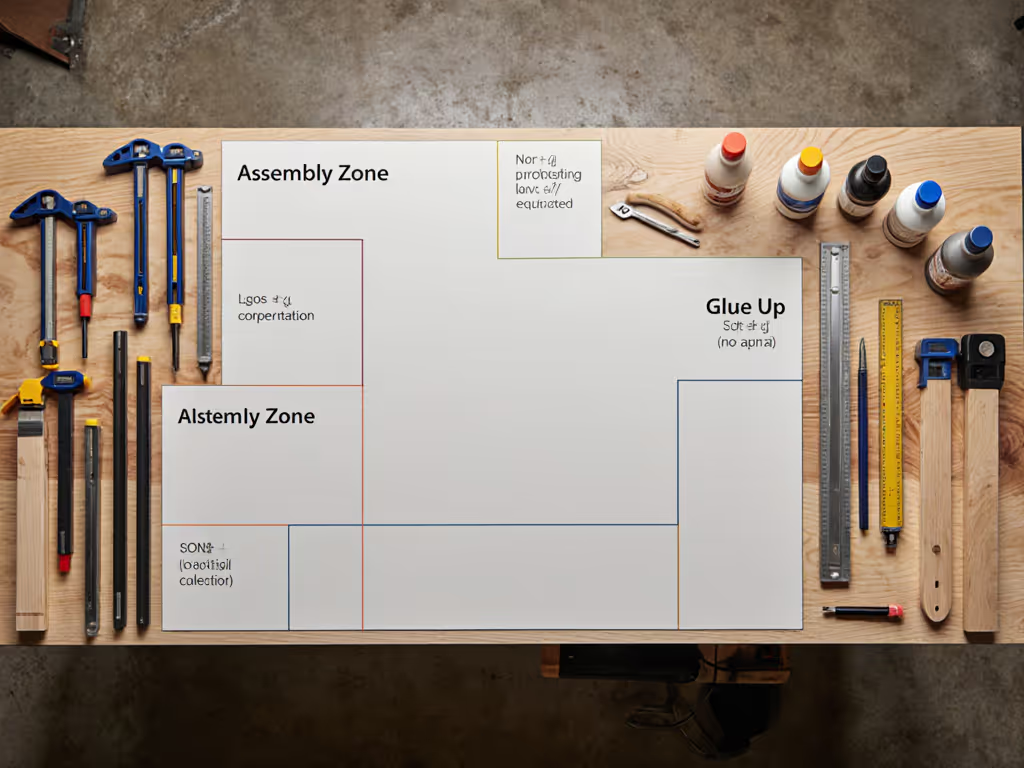

- Zone your surface: Left for assembly (clear), center for cutting (protected), right for glue-ups (easily cleaned).

- Dog holes matter: Place them where you actually clamp, never centered. Most beginners misplace them by 6+ inches.

- Surface prep: Apply paste wax to hardwood tops weekly. It repels glue and makes tools glide. For steel, use a light machine oil to prevent rust. For step-by-step care that prevents rust and glue buildup across different surfaces, see our workbench top maintenance guide.

Remember: Clear homes end clamp hunts. Every tool has a slot on or under the bench, not buried in a drawer.

Final Thought: Your Bench Is a Tool, Not a Trophy

The perfect woodworking workbench top isn't the priciest, it's the one that disappears into your workflow. It handles the punishment of daily use so you can focus on the craft. Whether you're eyeing a maple slab or a steel top, start by designing your workflow first. Then choose the surface that serves it. That's how you turn a cluster of tools into a command center where projects actually get finished.

Clear homes end clamp hunts, and confident craftsmanship begins.